DYNA MOTION

Provide Professional

Motion Control Solutions

Product Categories

OUR PRODUCTS

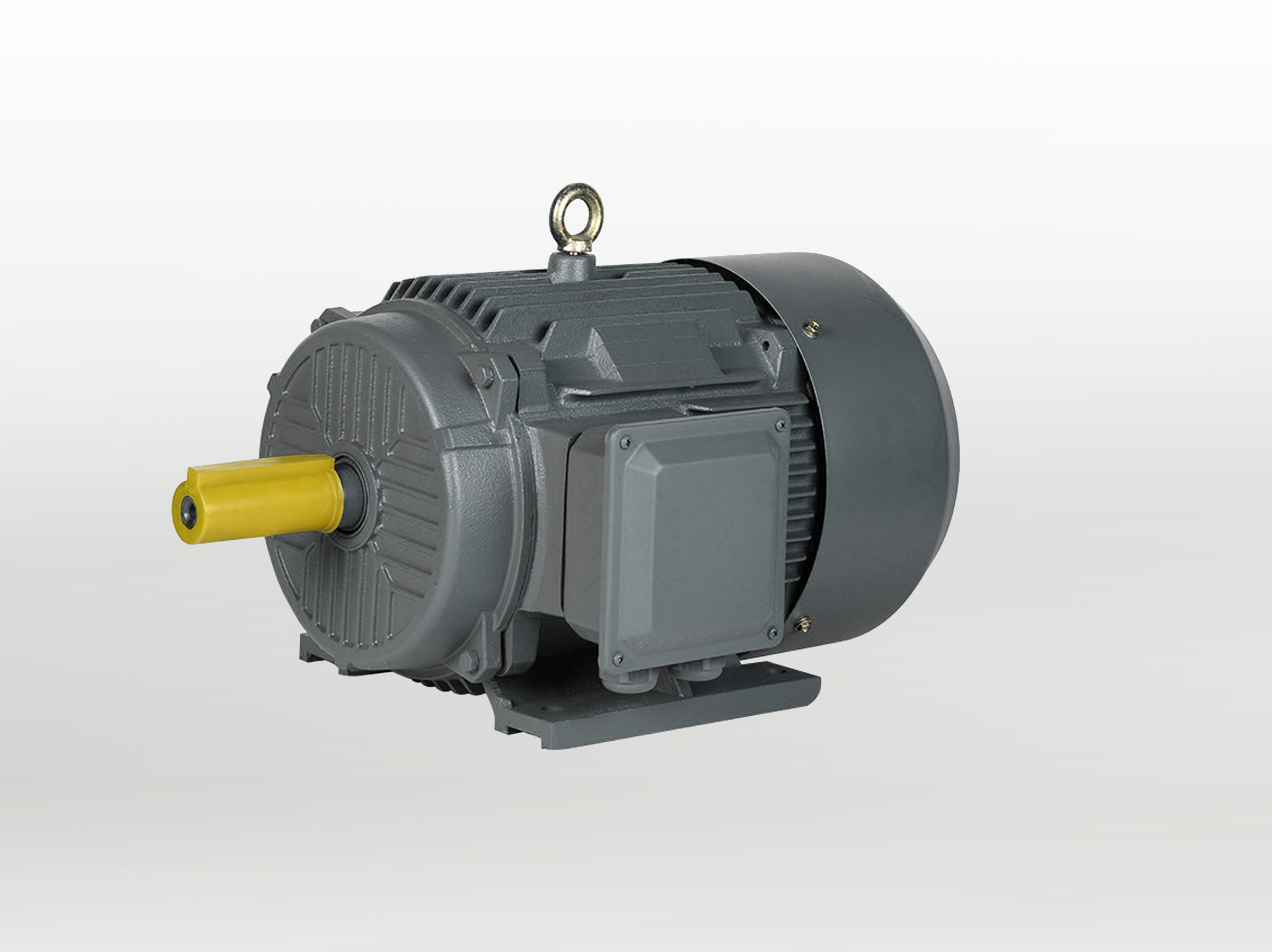

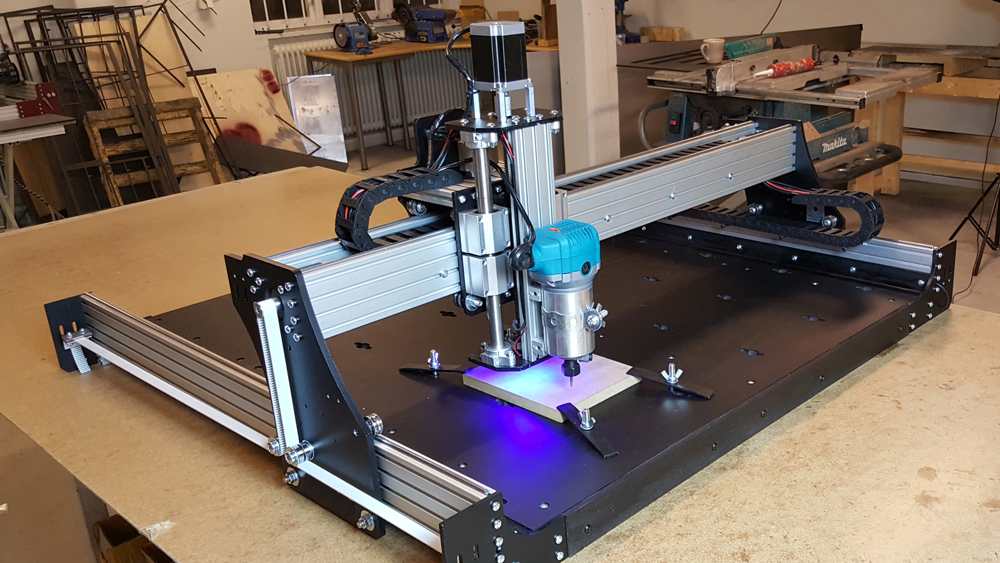

Our product portfolio encompasses a diverse range of high-performance electric motors, including servo motors, AC asynchronous motors, permanent magnet synchronous motors, stepper motors, linear motors, and electric actuators.

Renowned for their superior performance, high efficiency, and cost-effectiveness, our products are extensively utilized across various sectors such as industrial automation, elevator lifter manufacturing, mechanical processing, HVAC systems, water supply systems, and many others. We have earned the trust of over 50 global customers, affirming our reputation for quality and reliability.

DYNA Motion

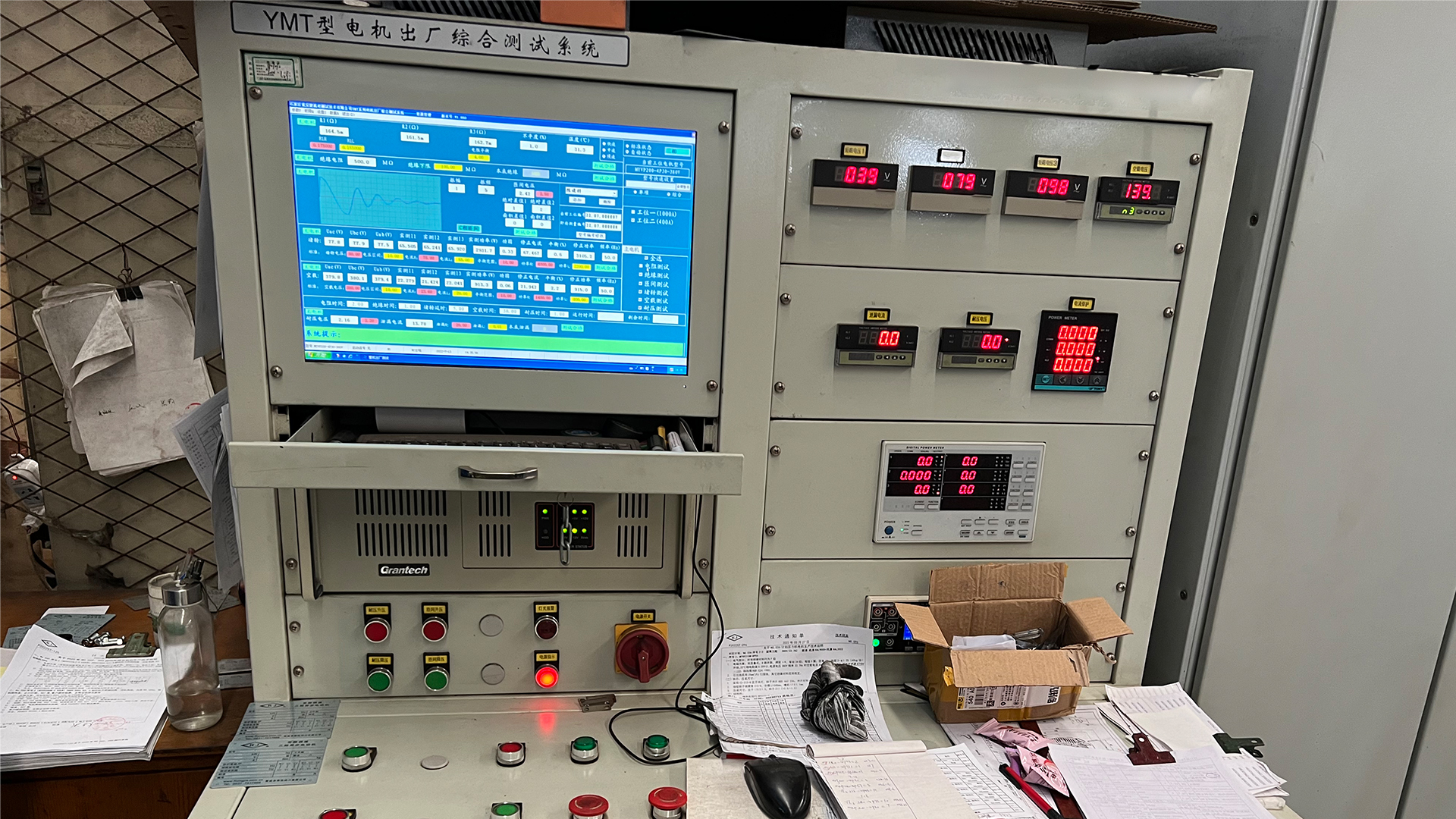

DYNA have a strong R & D team and manufacturing capabilities, with professional brush motor, brushless motor production lines and servo motor production lines, through years of technology accumulation and product customization of key customers, to help customers create outstanding final products.

Our motors are extensively utilized across a spectrum of applications, including industrial automation, HVAC systems, water supply systems, elevators, and household appliances. Our products have garnered extensive acclaim from our clientele for their performance and reliability.

Application Industry: Textile equipment, ceramic equipment, water supply equipment, printing equipment, stone equipment, food equipment, fan equipment,conveyor belt equipment, wood working equipment, industrial washing machine, ect.

APPLICATIONS

Industrial Automation Production Line

Automatic door operator motors are specifically designed to power and control the opening and closing of automatic doors. These motors play a vital role in the smooth and efficient operation of various types of automatic doors, including sliding, swing, revolving, and overhead doors. The motors used in automatic door operators must be durable, capable of handling frequent usage cycles, and designed to withstand varying environmental conditions.

HVAC Systems

Machines

Pumps and Fluid Handling

Electric motors power countless pumps and fluid handling mechanisms. Any time a fluid is moved or dispensed; it is likely done so by an electric motor. This includes the soap dispenser in the washroom at work, chemical sprayers for lawn treatments and even the soda dispenser at your favorite fast-food restaurant.